It should come as no surprise that even these simple holemaking tools can give better tool life and improved finish when used with care, and it should be equally well known that understanding how they work best, and how to make the right choices around using them, will give the best results.

Take a few minutes to read this little guide, putting these principles into practice will repay your time and effort the first time you use them and every time thereafter.

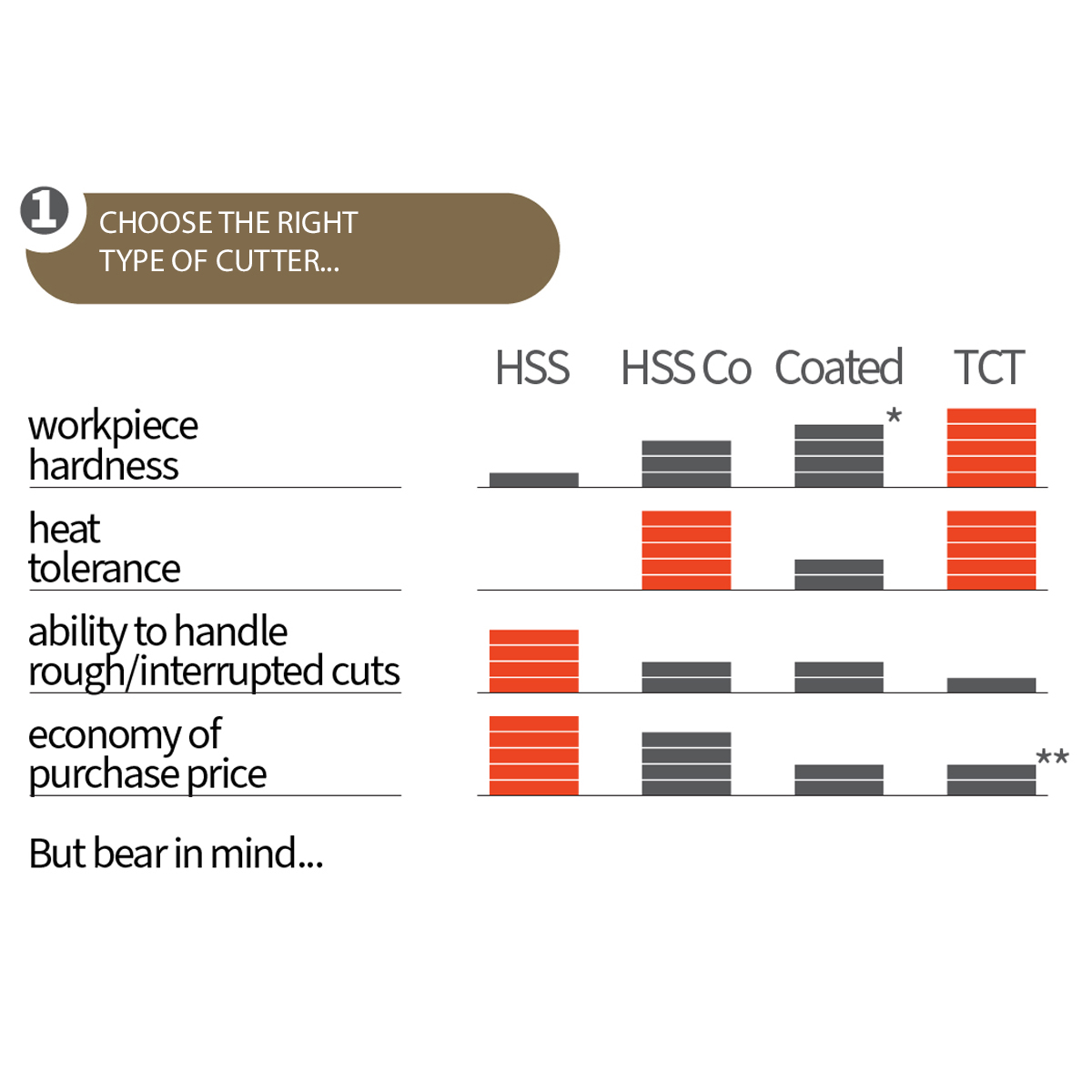

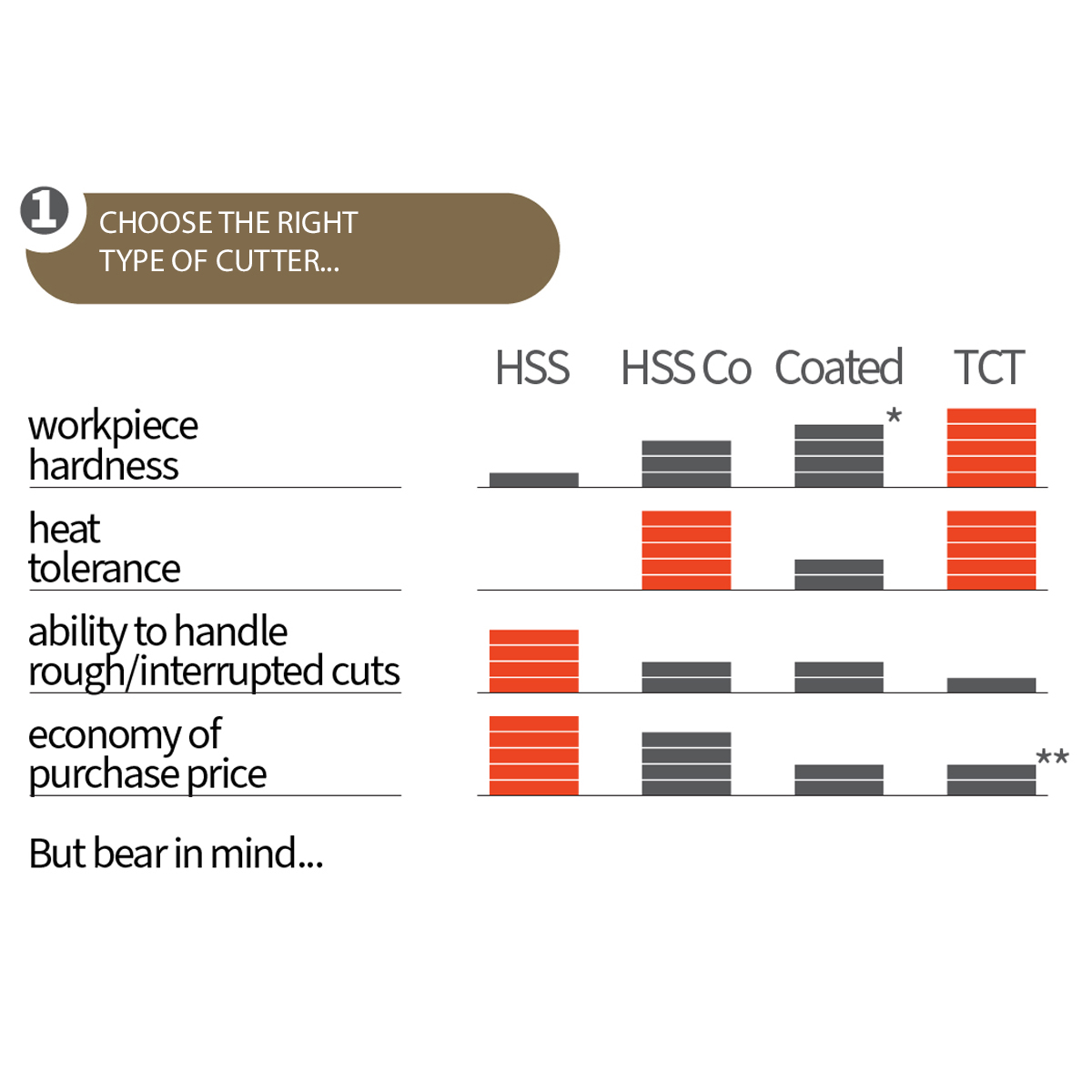

HSS cutters are the softest, so go blunt the quickest and can’t be run hot. HSS Co can be run up to blue hot. TCT teeth tend to fall off when the solder gets hot enough to melt. However, softer cutters are less prone to shattering.

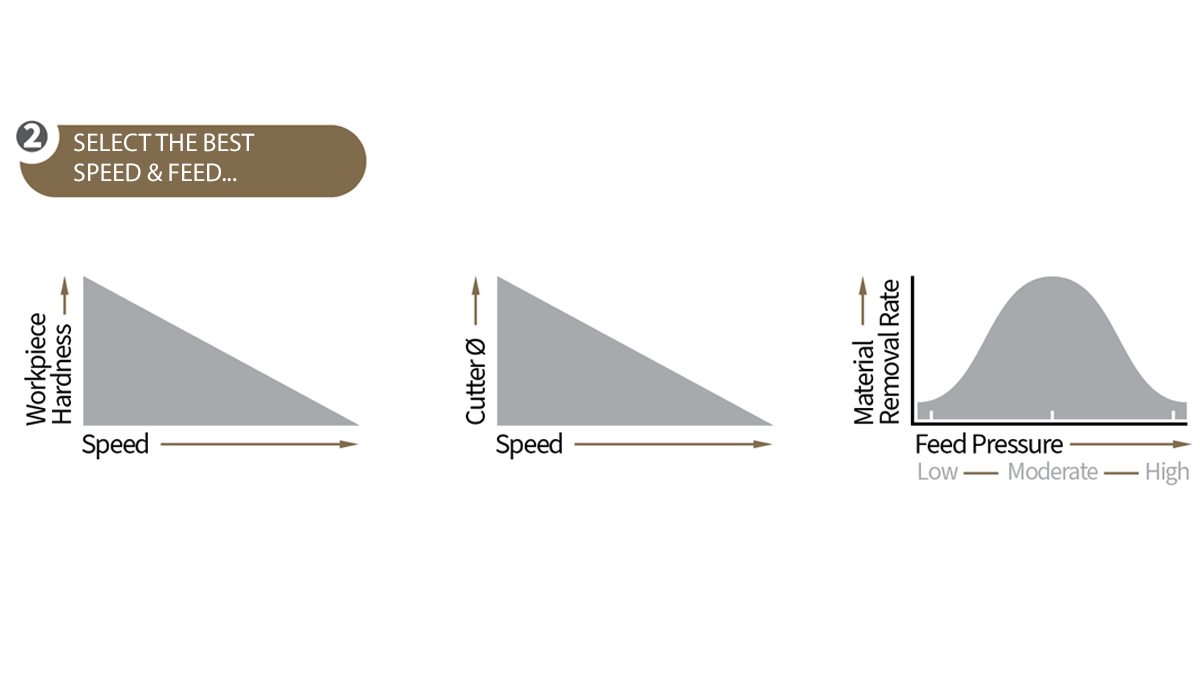

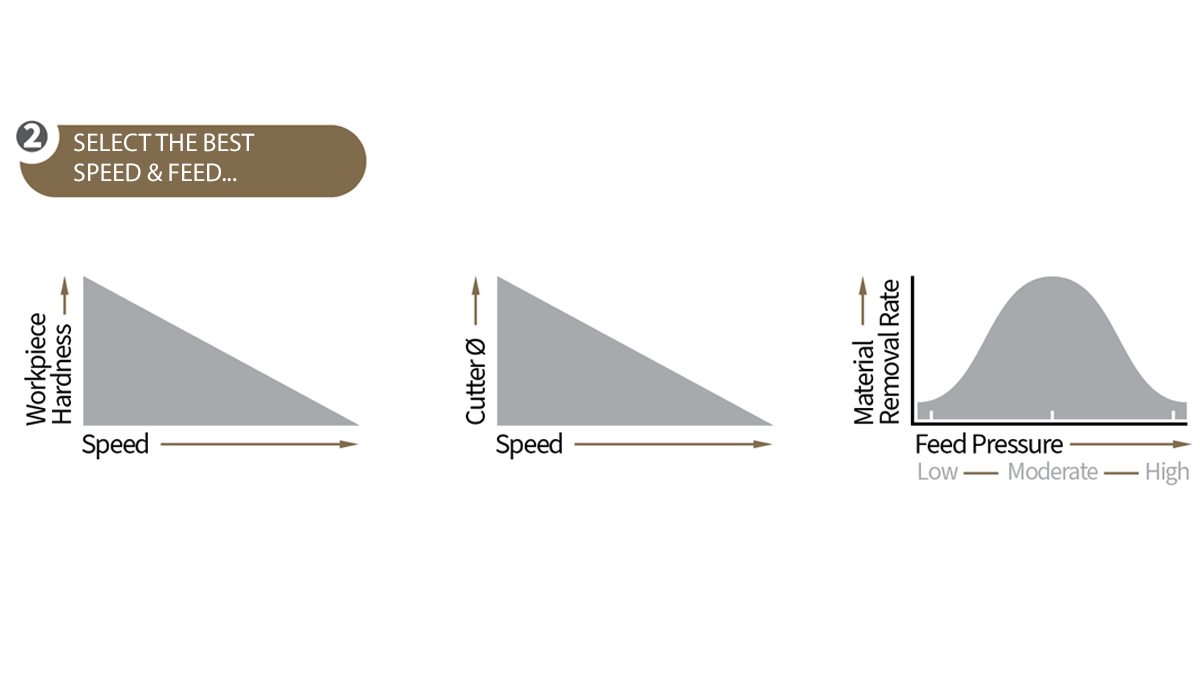

Many machines are only single-speed or two-speed, better machines have variable speed control. On pre-set speed machines, your only avenue to optimum cutter life when using larger cutters or drilling hard materials, is to use a carbide tipped cutter and/or copious quantities of lubricant.

Optimum material removal rates are achieved by using moderate feed pressure. If your cutters need excessive pressure it's a sign they are not sharp. Too low a pressure will increase friction and quickly dull off sharp cutters.