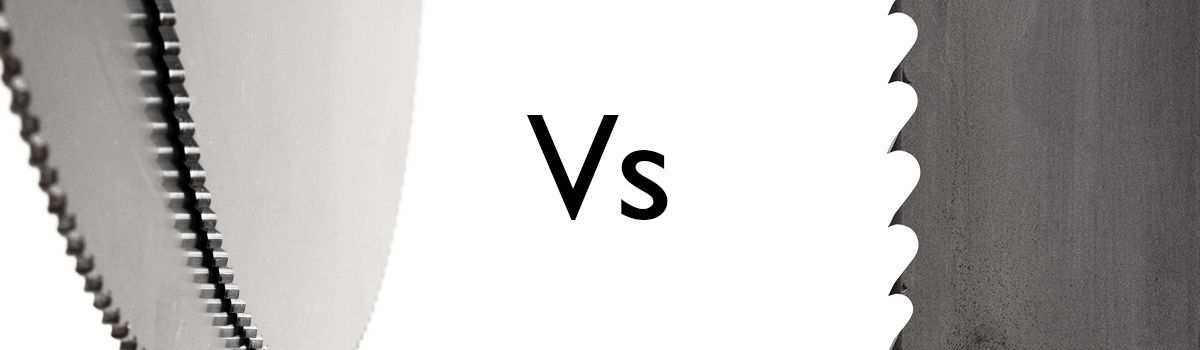

A situation we commonly come upon is that of customers wanting to purchase a new saw, but unsure whether that should be a bandsaw or coldsaw machine. In this article, we’ll try and address the pros and cons of each, and give our honest opinion on what best suits different situations.

For clarity, this article will be largely comparing manual coldsaws & bandsaws.

Cutting Capacity vs Cost.

If machine quality is comparable, a bandsaw will almost always have the greater size capacity for the dollars you spend. A decent size & quality coldsaw which takes a 350mm blade will cut around 120mm in diameter when the blade is new, and will set you back around $6K. By contrast, a good quality manual bandsaw for that money will cut 250mm. Note, as a coldsaw is sharpened the capacity of that blade will be reduced, whereas a bandsaw’s capacity stays constant.

Angle Cutting Ability

In terms of the degree range and ease of setting the machine for angle cutting, most coldsaws and bandsaws score similarly. The size capacity of both machines reduces the greater the angle, but the size of the reduction is greater with the bandsaw.

Speed

For single piece operation and especially for smaller or hollow sections, coldsaws are the quickest cutting. However for large solids, or if you want to cut a bundle of material in one shot – bandsaws have the edge, especially as bundle cutting in a coldsaw is near impossible! Bear in mind that with the coldsaw the operator must be present, whereas with most bandsaws the machine can be set to cut whilst the operator performs other tasks.

Finish & Tolerance

If you need a perfectly accurate, almost milled finish quality it is hard to go past a coldsaw. That said, bandsaw accuracy has come a long way compared to several decades ago, and a consistent 0.05mm tolerance is now pretty standard. The finish quality produced by either a bandsaw or coldsaw is also helped by a good quality blade, and the use of ample concentrate in your coolant mixture.

Consumables

Bandsaws easily win when it comes to the cost of each cut. Firstly, a bandsaw blade allowing a cut capacity of 250mm generally costs $50-75, whilst a coldsaw blade allowing a capacity of 120mm costs around $300. You use the bandsaw blade till it is dead and then biff it, whereas the coldsaw blade gets sharpened at a cost of approx. $30+, which is some added hassle. The bimetal blades used on bandsaws are usually a higher grade (M42) of steel than that used in a standard coldsaw blade (M2), and this gives them another advantage, as well as a lot more teeth to share the wear over.

Maintenance

We don’t consider either machine type to be high maintenance, but bandsaws are probably slightly higher – this is mainly due to the blade guides needing occasional refurbishment. Other than that, both coldsaws & bandsaws need regular cleaning and coolant changing. In summary, bandsaws far outsell coldsaws for good reason. However, coldsaws still have their place and are not likely to lose it in the foreseeable future.