There are three main ways a blade can quickly lose its edge, select each heading below to go more in-depth.

Premature blunting

Usually makes itself known by an unexpected and early-onset increase in the cutting time and is often accompanied by a buildup in heat.

The most common cause is incorrect run-in procedure, failing to carry out this vital step is to guarantee that the blade will wear much sooner than it should. Another likely cause, generally in harder materials such as tool steel or stainless, is either a feed rate that is too low or a blade speed that is too high, leading to the teeth skidding over the workpiece surface rather than penetrating and cutting the material, building up friction and heat that can damage the blade and even harden the workpiece in some materials. If you’re sure of your speed & feed settings and are confident they aren’t the problem, it might be worth double-checking your tension. If the tension is too low, it could add to the tendency for the blade to skid over the material rather than bite in as it should, although there will be other signs that this is the problem in most cases.

The blade may not be receiving enough lubrication and cooling from the cutting fluid, so check that the coolant concentration is correct and that the fluid is making it to the cutting zone in sufficient quantities.

You also need to consider the workpiece itself, as the material being cut could simply have defects such as hard spots or other hardening that effectively makes your selected speeds & feeds less suitable.

Less likely, but something that we see more often than we probably should, is running a blade backwards so that the back of teeth run across the material rather than the teeth cutting into it. Make sure the blade is correctly oriented as soon as a lack of cutting is noticed on a newly fitted blade.

Although it should be obvious, it’s probably worth mentioning that if a blade is already worn and dull when you put it on the saw, it will be wearing faster than a sharp one unless the feed rate is increased to maintain sufficient penetration. If it isn’t penetrating the material efficiently, this will lead to more heat being generated, leading to more wear, more heat, so more wear and so on.

It’s also possible that the sharp new blade you’ve fitted is just not up to the job, but if it’s a Brüel blade that we’ve matched to the work you’re doing, that’s not going to be the case.

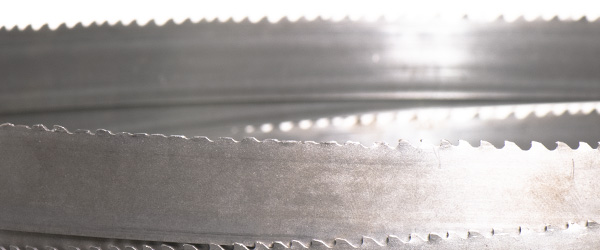

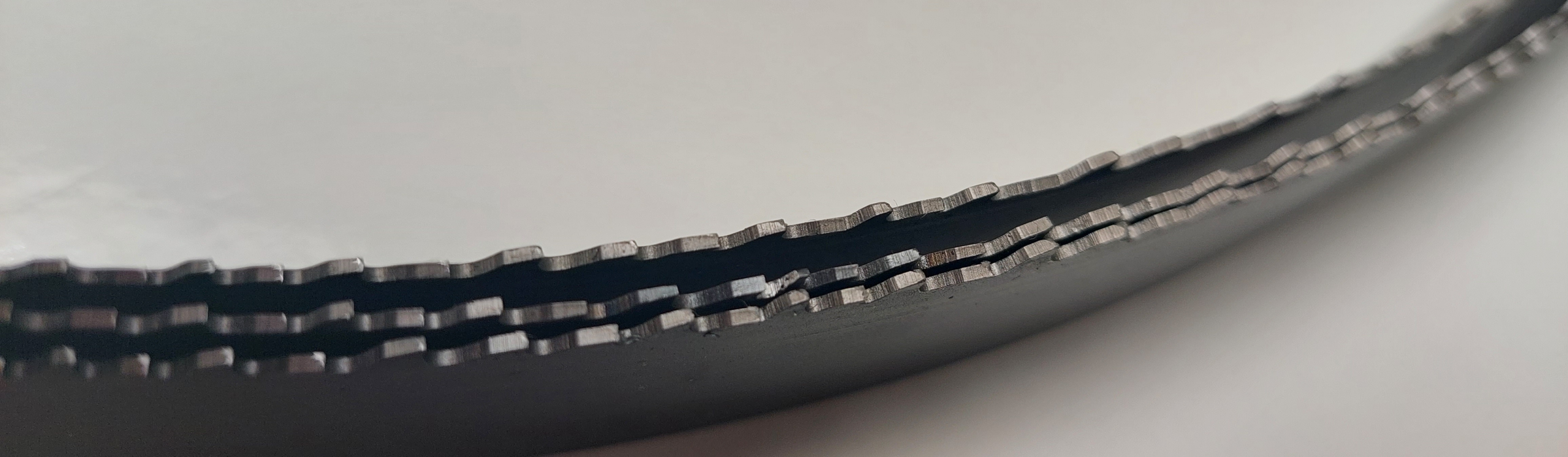

Teeth wearing flat

If portions of your blade show teeth that have visibly flattened tops, you have a significant issue that should be solved before you go any further. Once again, the first thing to look at is run-in procedure. We can’t over-emphasise the important of run-in for blade health, if there are 10 things you should tell yourself to get the best from your blades, correctly running them in would be nine of them!

As mentioned above, check that the blade is running the right way. It’s difficult to imagine a blade being put on to run backwards, it would have to be ‘flipped inside out’ for this to happen, but it is something that we do see on occasion. In these circumstances it’s inevitable that the backs & tops of the teeth will wear quickly and badly – the back of the tooth has no chance of cutting, although it can grind through some materials with disastrous results for the blade.

Something else that we mentioned earlier was the chance of the workpiece containing a hidden hard spot. Metal is a ‘natural product’ and is therefore subject to some variation, unexpectedly running into these can result in a sequence of flattened teeth. This is typically a localized problem limited to one or two areas on the blade, at least at the start, but continuing to run the damaged blade will quickly spread the damage as the remaining teeth take up the slack and become overloaded. It’s unavoidable, so you’ll need to recognize the possibility of this being the cause when it happens, mostly by eliminating the other options.

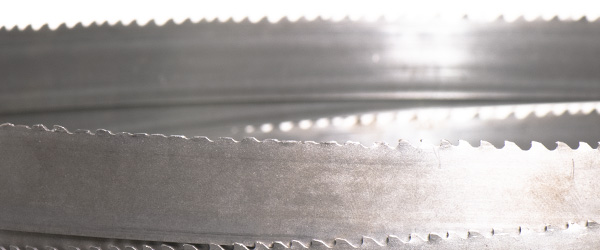

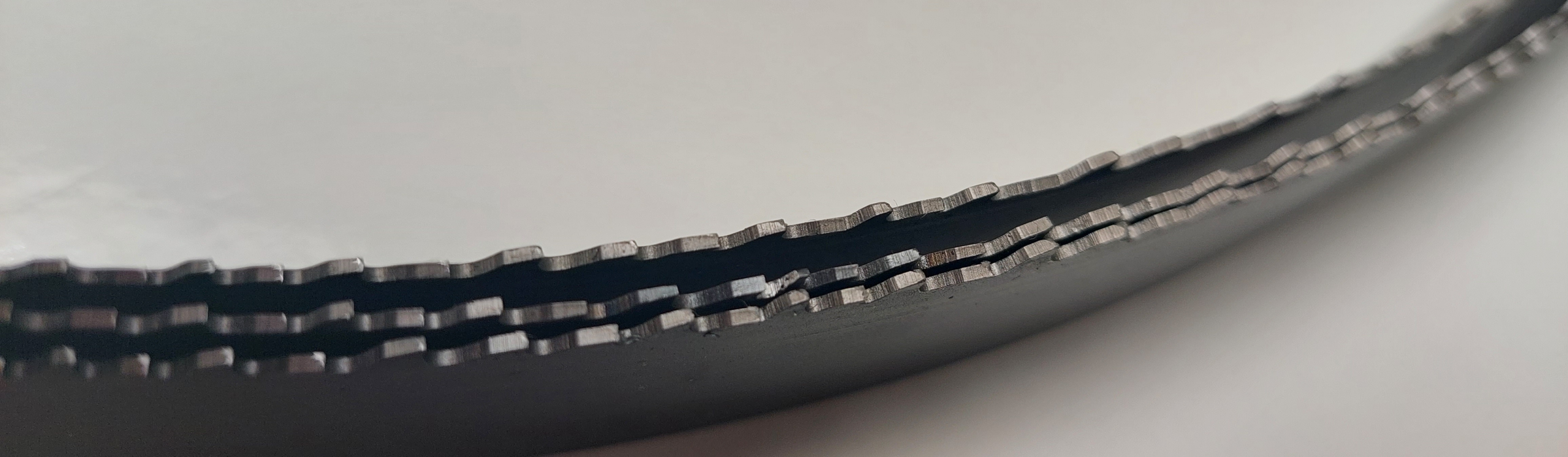

Tooth 'set' wearing off one or both sides

Bandsaw blade teeth have a set, with teeth aligned slightly to the left and right of the blade’s centre-line to provide clearance through the cut which is essential for smooth, effective cutting. If one side of the set has been worn off, you’ll probably also be seeing the blade make curved cuts, curving in the direction of the side that still has good set. If both sides of the set are worn equally, it’s less likely that the cut will curve in the same way although there will be other clues such as variance in the cut surface and generally needing more time/effort to make the cut. But what’s causing the loss of the set?

The most likely cause here is either the machine’s guides being badly set, so that the blade is running at a slight angle through the cut, or we’re back to those hard spots in the material again for the other most common culprit. In the case of hard spots, it's pretty much always going to be side of the blade that hits it which suffers the wear. It’s theoretically possible that the blade will go through the centre of a hard spot, which would wear the set evenly, but in reality that’s unlikely.

Another thing to look for is your machine’s camber, does the blade run so far back on the wheel that the teeth no longer hang off the edge? If the teeth are running on the wheel itself, the teeth will lose the set on the ‘inside’ of the blade.

And if the set is affected on both sides, check the blade has sufficient tension. Also, ensure the workpiece does not tend to fractionally close up as the blade cuts through, pinching the blade. This will further reduce the set and may eventually jam the blade and cause it snap. It would also be the result of running a new blade into an incomplete cut made but an older blade, because the set naturally slowly wears off as a blade is used. What this means is if you run a new blade through an older blade’s cut, it will immediately wipe the side off the set on the new blade to match the older blade.

It's best not to continue with a blade that has lost any of its set, making it perhaps the most frustrating of all blade issues as, technically, the teeth are still ‘sharp’.