That’s probably a redundant question, isn’t everyone looking for the same thing? And when cut accuracy and finish are paramount, you can’t look past a coldsaw to deliver the goods.

Well, that’s never going to be the case, of course, and anyway, you actually want there to be differences to provide you with a commercial benefit that your competitors may not enjoy. Choice and variety are good, so you need to embrace them and understand how to gain that commercial edge through better suited cutting fluid choices, but that just sounds like a lot of effort!

How do coldsaws make cleaner cuts?

Don’t worry, we’ve done the hard work for you – here’s a comparison of the different ‘groups’ of cutting fluid and what they’re designed to do. It’s not an advert for any of the types, it’s to help you understand what you need for your machines, so you can make better choices and get more from your spend on these liquid assets. So let’s look at the major differences, with some Pros & Cons for each – but remember these are generalisations and some specific formulations are created for specific atypical requirements, so not every option out there will fit these generalisations.

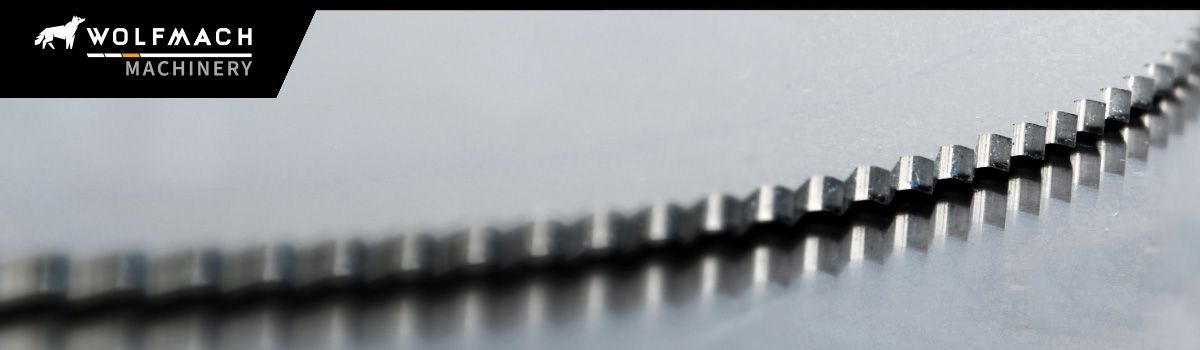

It’s true that bandsaws have come a long way and some can now get very close to matching the cut quality of a coldsaw, but there’s still nothing to beat the quasi-milled finish that a simple, stable coldsaw can produce and that’s down to the difference in how the machines cut. Unless conditions are perfect, the bandsaw blade is always going to be subject to factors that the coldsaw doesn’t have to contend with. The coldsaw employs a relatively thick disc of high-speed-steel slowly turning concentrically and shaving metal off the workpiece with an endless array of ground & honed teeth. By comparison, a bandsaw’s somewhat springy strip of flexible, thin steel that has to be twisted through up to 90 degrees to make the cut is going to need much greater control from the design and build of the machine. Don’t take this the wrong way, a quality modern bandsaw is a superbly engineered piece of kit that has many advantages over a coldsaw and can easily make clean cuts through the workpiece, but the coldsaw can just make a more reliable clean cut as the process itself is subject to far fewer variables. In ideal conditions, a good quality bandsaw can get very close to the coldsaw’s cut quality, but in real-world workshops and actual-case working conditions, the coldsaw will generally give a cleaner cut than a bandsaw most of the time.

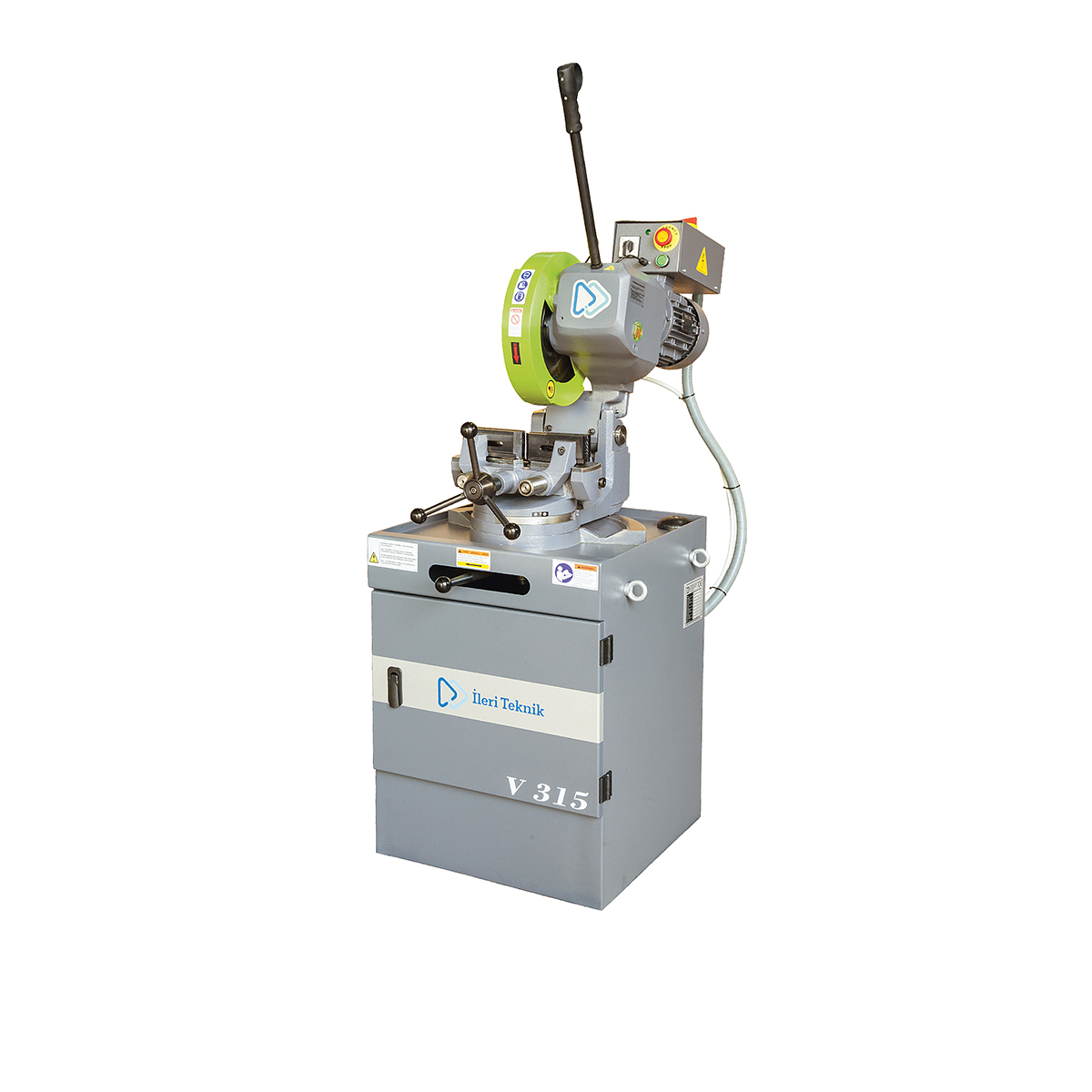

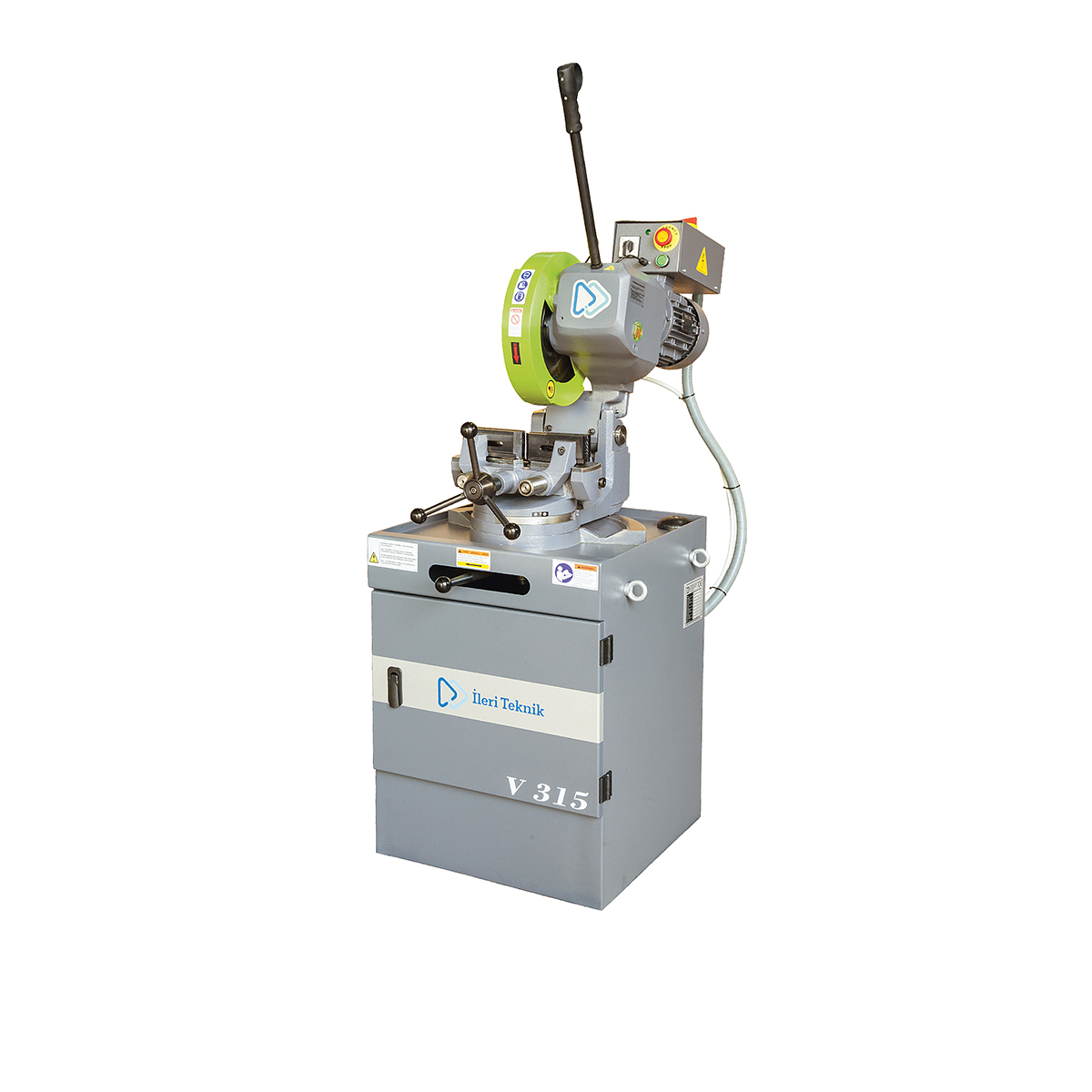

Ileri’s manual models are robust, simple to operate machines that provide about the best cut quality available (when used with a good quality, well-sharpened blade such as the Italian Grossi range) and they have a very small footprint, making them a useful addition to practically any workshop.

This SMC315M-3FV has hand-lever operated powered clamping and a low-voltage start/stop trigger switch within the pull-down handgrip, making it easy to achieve a highly professional cut. 45 degree mitre cutting at both sides makes for good practicality and efficiency.

It comes with a fixed rear vice, making it easy to use with roller tables and accurately position workpieces for cutting. A centering vice version is also available as an indent purchase.

With two cutting speeds, robust double-hinged pivot and counterbalance spring, this is a simple to operate and compact machine that makes easy work of everyday cuts that require little to no further finishing.

The Ileri range of coldsaws includes a wide range, from simple manual machines to fully automated cutting systems.